Launching RealCold as a Differentiated Cold Chain Company

Keith Goldsmith, Chief Executive Officer

Last updated: Dec 20th, 2024

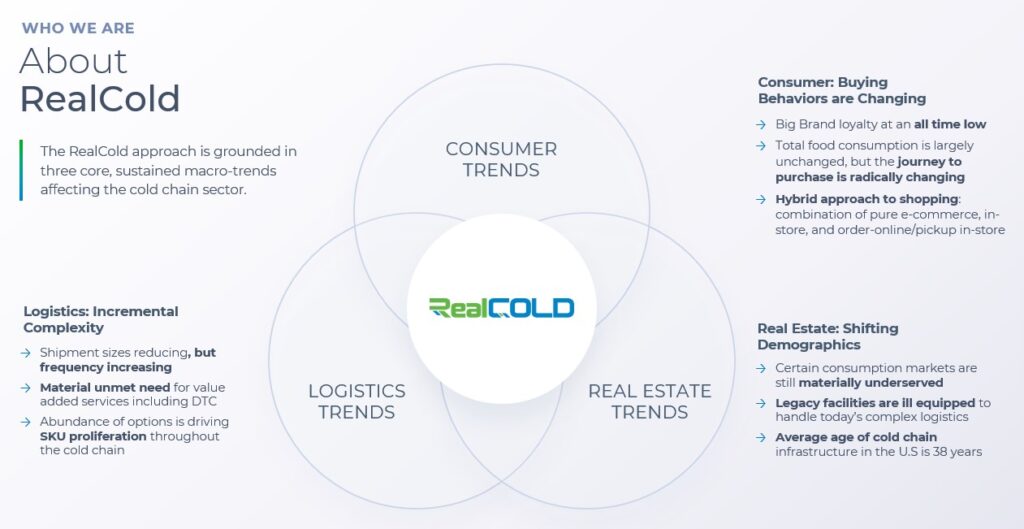

It is impossible to attribute the genesis of RealCold to a single event or date, rather the impetus for founding the company stems from the amalgamation of various “aha moments” over a decades-long career across both dry logistics and temperature-controlled logistics supporting the food industry. My time at some of the largest players in the sector, coupled with my tenure at boutique consultancies provided me with unique perspectives regarding underserved white spaces that can be synthesized into three distinct but related buckets, and that ultimately became the thematic on which RealCold would be built.

Theme 1: Logistics Complexity

The consumer is demanding more choice, diverse flavors, and healthy options, and food entrepreneurs are stepping up to meet these demands by spinning up new brands at a dizzying rate. As you walk down a retailer’s freezer aisle the number of brands that didn’t exist even five years ago represents an increasing portion of cooler shelf space. This abundance of options is driving SKU proliferation throughout the cold chain. As a result, inventory strategies are shifting, specifically, shipment sizes are being reduced but frequency of shipments is increasing.

Concurrent with this change is a rise in the need for value added services such as labeling/relabeling (for big box and club stores), pallet management (assembling rainbow pallets or aisle friendly pallets), and case picking.

I have witnessed that incumbent cold chain providers perform these services begrudgingly, and only when the size of the customer justifies these investments. The recognition that the need for such services has advanced from “nice to haves” to core requirements served as a catalyst to establish RealCold as an executer of value added services (VAS) as a primary offering rather than a secondary one.

When evaluating these VAS requirements, coupled with the additional complexity associated with SKU proliferation, it becomes apparent that the once basic pallet-in/pallet-out business is no longer so basic. To address the depth of logistic challenges, RealCold hired skilled engineers as some of our earliest employes, brought on to design and deploy streamlined solutions that account for the changing marketplace and newly in-demand services. With these resources in place, we apply a rigorous and collaborative process to develop a right-sized, comprehensive, yet scalable cold chain solution for our customers.

Theme 2: Consumer Buying Habits are Changing

The future of food is omnichannel and the journey-to-purchase is radically changing. Traditional grocery stores, online marketplaces, subscription services, and meal kit companies are all part of the same ecosystem. Consumers no longer distinguish between these channels; they expect seamless experiences regardless of where they shop. They are ordering online and shipping to homes, ordering online and picking up at store, and ordering online and fulfilling through platforms like Instacart.

Double-clicking into the first of the buying paths, ordering online and shipping to home (or simply put: e-commerce), this approach disrupts the historic food supply chain sequence, often omitting the store altogether. Many frozen and chilled brands cannot execute this in-house and will look for an external partner who has mastered these capabilities. Ideal partners will need to have the following robust resources:

- A national network of cold storage facilities to enable distributed order fulfillment

- Technology systems to integrate common selling platforms (Shopify, Amazon, etc)

- Skilled operators to pick at the each-level

- Rigorous processes and systems to ensure pick-and-pack accuracy

- Systems with logic to optimize cartonization

- Competitive parcel rate cards and a network of delivery partners

Unfortunately, there are not many cold chain providers who can offer these as core competencies and have demonstrable success. Recognizing this as a gap, we opted to establish RealCold as a provider that could perform not only pallet-in/pallet-out activities, but as one that specializes in direct-to-consumer (DTC). This was achieved by acquiring Forte Frozen, one of the predominant cold & frozen DTC providers, in October of 2023. We have been continuing to deliver on the Forte Frozen team’s years of success in the space and further up-level the capabilities with investments in people, processes, and technologies to reinforce RealCold as the de-facto choice for DTC.

Theme 3: The Impact to Real Estate from Shifting Demographics

Incumbent cold chain providers have reached maturation through traditional pallet storage, and have done so by leveraging infrastructure that is appropriate for the needs of yesterday. This is reflected in infrastructure that is nearly 40 years old on average. Such facilities are not as efficient as modern warehouses both in terms of sustainability and scalability. Moreover, these tend to be located in areas that are more rural and away from the end consumers.

However there is a growing for facilities to be in urban centers and high consumption markets to meet the needs for rapid replenishment and provide expediated delivery of products to end consumers via DTC channels per Theme 2 (it should also be noted that the earliest and highest adopters of new buying journeys [i.e. e-commerce] are usually anchored in fast growing MSAs as opposed to rural areas). As such, certain markets are materially underserved in having proximal modern facilities that can serve as both a distribution center for retailers and as an e-commerce hub for next-day delivery to end-consumers. These facilities must be designed thoughtfully to include such features as:

- Multi-temp offerings

- Eco-friendly and sustainability-focused design elements

- Optimized for DTC fulfillment

- High throughput

- Flexible racking

For RealCold our market expansion strategy is driven by consumer demand. This is reflected in our three newest builds which are all strategically located in fast growing MSAs, specifically our Lakeland Florida facility between Orlando and Tampa, our Lockhart Texas facility, between Austin and San Antonio, and our East Hanover New Jersey facility, which can serve the tri-state area of New Jersey, New York and Delaware, as well as the broader northeast. These forward-stocking locations meet the demands of food manufacturers, food service providers, retailers, and digital native brands more effectively than older infrastructure further away from consumers.

Additionally, the RealCold facilities have been designed with the future in mind, allowing them to flex to the needs of customer requirements by leveraging fully convertible rooms, efficient layouts, and multiple racking options. These facilities have also been engineered for efficiency, earning them LEED certification. Augmenting the modern features is an enterprise grade WMS which aids in the orchestration of even the most complex requirements, and which provides visibility and transparency to client inventories.

Summary

The pillars on which we have built RealCold position the company not just as a competitor to the incumbents, but bestow unique differentiators which we believe allow RealCold to be the preferred vendor for progressive and evolving companies in the food sector. We look forward to demonstrating our broad array of services, our DTC capabilities, and our next generation warehouses, as they are the reason why our tagline is Cold Chain Unchained.